Preventive Maintenance Software Streamlines Operations

Maximize Uptime

Exceed your production goals! Keep equipment running smoothly and efficiently by preventing breakdowns before they happen. Say goodbye to equipment emergencies and hello to seamless operations.

Ensure Compliance

Strengthen your preventive maintenance program with audit-ready historical records of assets and maintenance activities. Get the reports you need to meet compliance requirements and make data driven decisions

Control Costs and Extend Equipment Lifespans

Prolong the life if your equipment by sticking to a preventive maintenance schedule. Well maintained equipment runs more smoothly and efficiently. Cut costs and keep equipment performing.

What is Preventive Maintenance?

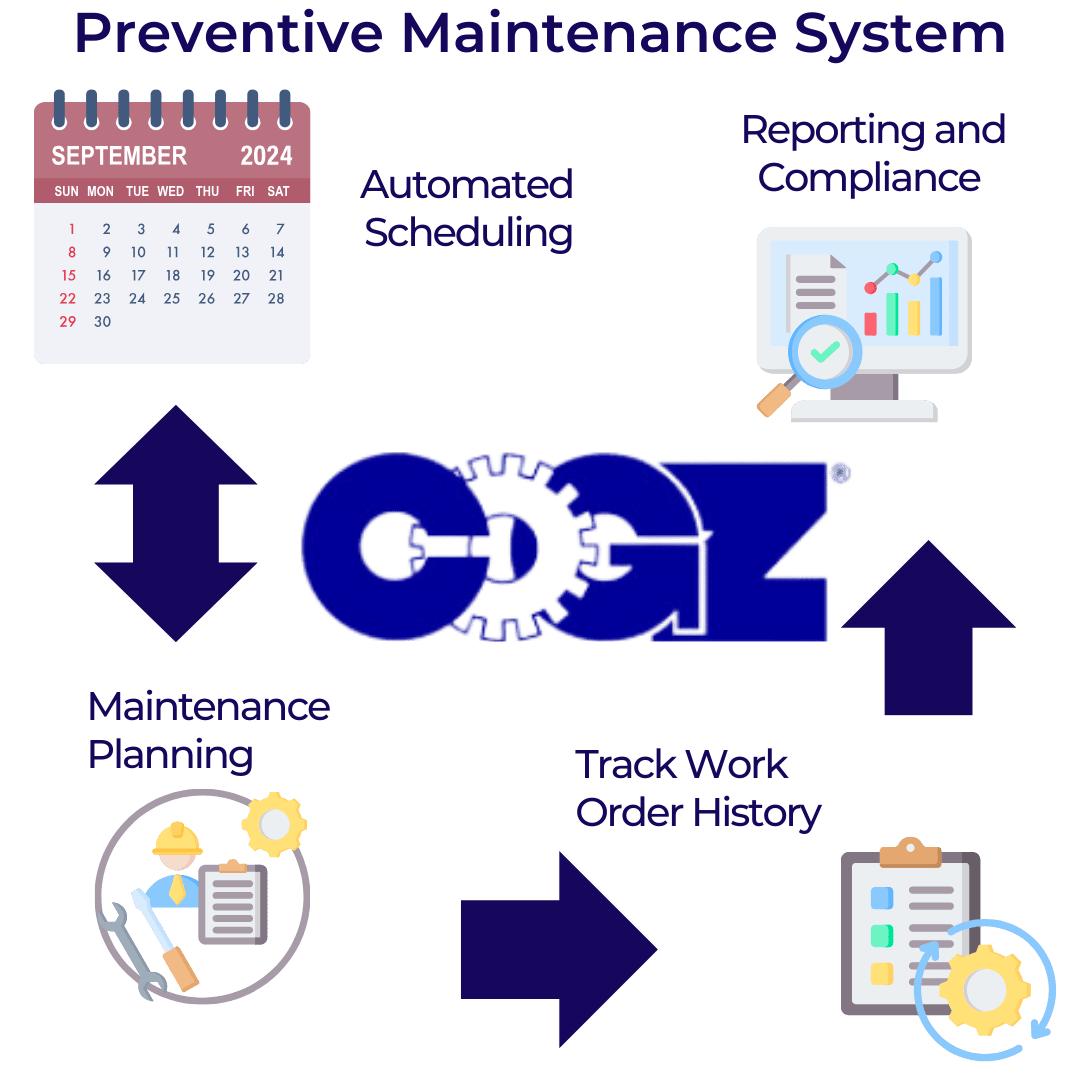

A Preventive Maintenance System is also known as CMMS (Computerized Maintenance Management System). It automatically schedules and tracks routine inspections and preventive maintenance tasks. Automating preventive maintenance ensures that work is completed consistently and on time. Completing maintenance on time saves time and money by reducing breakdowns and extending equipment lifespans.

Preventive Maintenance Software is a complete maintenance solution that tracks your equipment and reoccurring tasks. The information the system gathers can also be used to perform predictive maintenance on your assets. These maintenance tools manage your entire maintenance staff. Improved reliability virtually eliminates reactive maintenance and the high costs that result. CMMS contains additional features beyond preventive maintenance including Work Order Management, Inventory, Management, Downtime Tracking, Vendor Management, and Purchasing.

What are Some Examples of Preventive Maintenance?

Preventive Maintenance includes regularly scheduled inspections, services and parts replacements with the goal of preventing equipment failure. Examples of common preventive maintenance tasks are:

- Inspections

- Lubrication

- Cleaning and sanitation

- Calibration

- Proactive parts replacement

- Testing emergency equipment

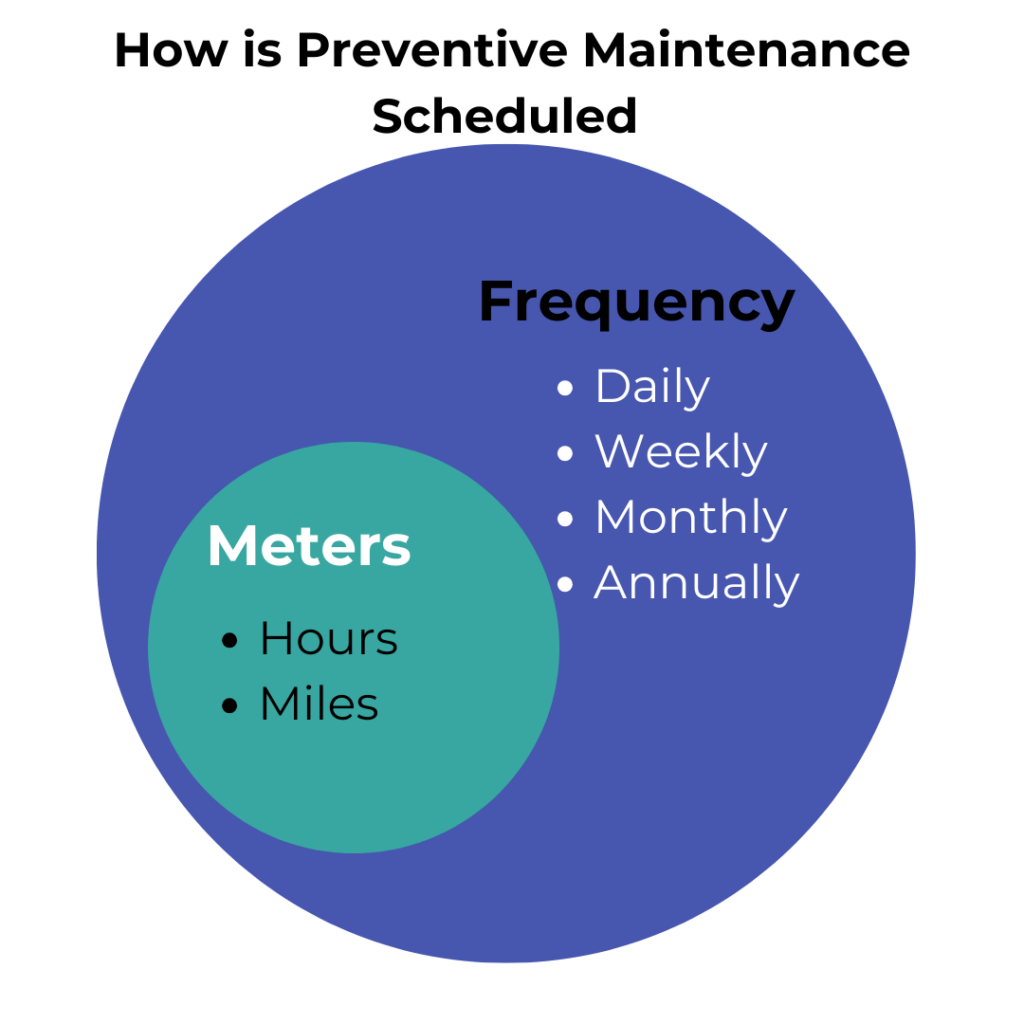

How is Preventive Maintenance Scheduled?

Preventive Maintenance is performed repetitively at regular intervals.

- Frequency (daily, weekly, monthly)

- Meter reading (miles, hours)

- Condition based scheduling

Preventive Maintenance Work Orders are automatically generated based on the date the task was last completed. They show up on the Work Order list and can be printed or emailed. CMMS Software has tools like the PM Wizard that make setting up your preventive maintenance tasks easy and fast.

Some Preventive Maintenance Systems allows work order requests which schedule reactive maintenance work orders.

How to Manage a Preventive Maintenance Program

Maintenance activities can be managed through various types of preventive maintenance systems.

- CMMS (Computerized Maintenance Management Software)

- Excel Spreadsheets

- Paper based checklists and logs

- Paper or electronically distributed work orders

What are the Benefits of Preventive Maintenance Software?

- Increase productivity by increasing equipment uptime.

- Increase equipment life span with on time preventive maintenance.

- Decrease maintenance costs by minimizing downtime due to breakdowns.

- Maximize existing resources with proper maintenance planning.

- Reduce stress on your maintenance team by working smarter.

- Identify which assets are costing the most money and why.

- Have the parts you need when you need them while controlling Inventory costs.

Integrate your Team with Preventive Maintenance Software

Automate Preventive Maintenance

Work Order Management

Equipment Management

Inventory Management

Purchase Orders

Vendor Management

Downtime Tracking

Comprehensive Reporting

Preventive Maintenance Software Features

Equipment/Asset Management

A Preventive Maintenance System starts with Equipment Management. Maintain a complete listing of your assets as well as their preventive maintenance requirements, diagrams and maintenance history. Our Preventive Maintenance Software features an Equipment Master Console which tracks all of this information. This powerful display shows all of the information on a piece of equipment on one screen including work order & inventory history and drawings/ documents

Automated Preventive Maintenance

Preventive Maintenance Software is the cornerstone of your CMMS. Schedule your preventive maintenance tasks and makes sure that you complete them on time. Performing timely preventive maintenance prevents breakdowns and expensive downtime. It keeps your equipment and facilities running smoothly, improves safety and productivity. Fight inflation by reducing unnecessary costs.

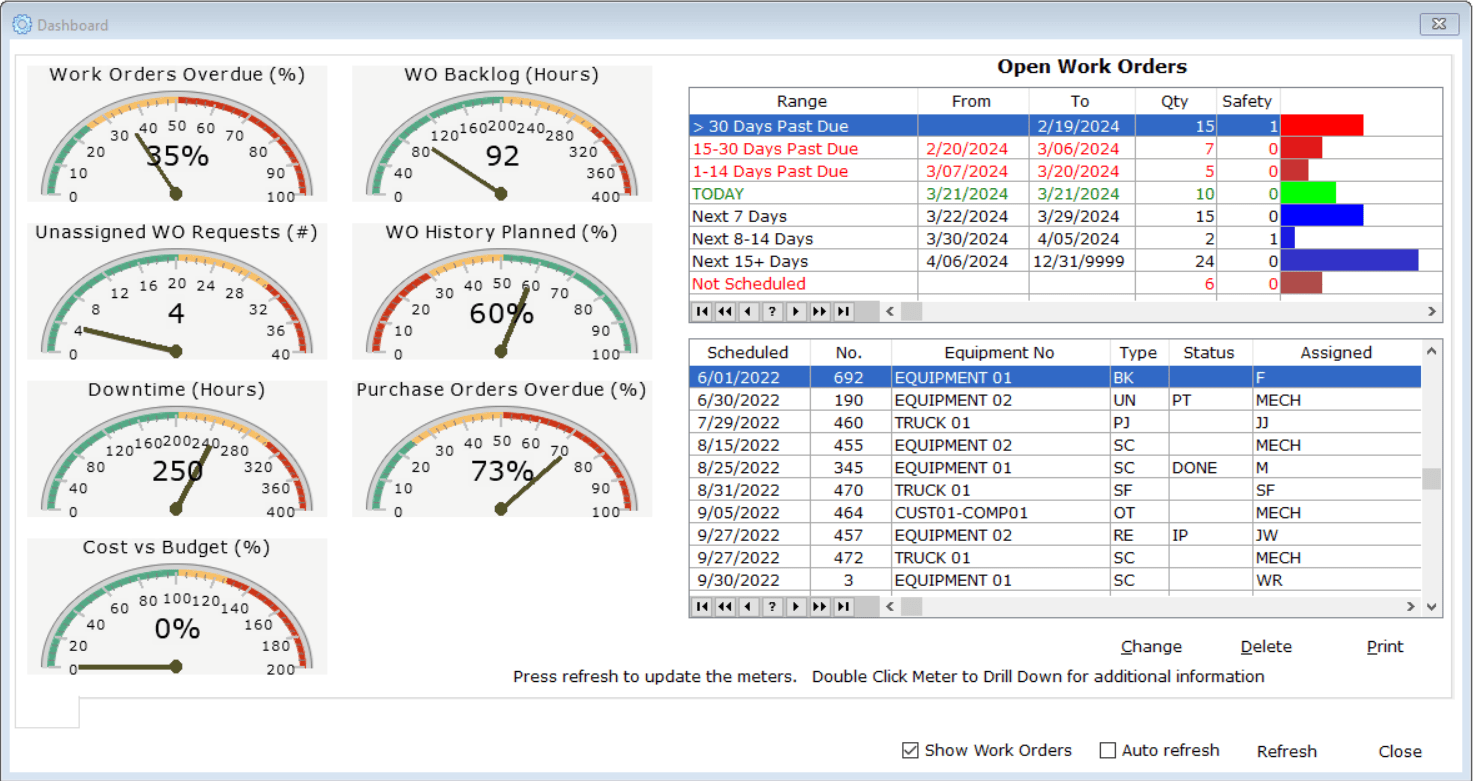

Work Order Reminder

Make work order management simple. The Work Order List displays all of the open work orders on a single screen. Enter labor and parts costs when work orders are completed. Track work order costs and see what equipment is costing you the most money. Work Order Reminder makes sure you never forget a work order. It notifies you when your work orders become overdue.

Assign Parts

Global Supply chain issues have made proper inventory management more important than ever. Track what spare parts you have on hand and knows when you need to reorder so you don’t run out. All inventory information is logged including cross references and alternative vendors, making it easy to find a substitute when needed. Backorders and expensive overnight freight will become a thing of the past. Lower inventory holding costs by having the right quantity of inventory on hand.

Frequency

Different tasks, different schedules. Preventive Maintenance Software allows a wide range of Work Order scheduling options. These options include Number of Days since last performance, and/or meter, miles or run hours. Get the flexibility to make your Preventive Maintenance System work.

Attach Drawings/Documents

Attach a drawing or other document to the PM Task and print it with the Work Order. Make sure your staff has all the resources they need to complete the work properly and efficiently.

Last Comment

Carry it forward. Need a reminder to bring a filter next time you change the oil? Make a note when you close the current work order and our Preventive Maintenance System will automatically add it to your next scheduled maintenance for this task.

Mobility

COGZWeb is Preventive Maintenance Software in the cloud. All you need is a web browser an an internet connection. Take our preventive maintenance software into the shop or the field. Go paperless by accessing and completing your work orders on tablets or laptops. Save time by having all of the maintenance data you need at your fingertips. Improve the quality of data entered with the ability to enter data as technicians do the job.

Reporting

COGZ offers a variety of reports and exports that display the maintenance data collected. Use reports and exports to analyze data and make informed management decisions. Maintenance Management becomes easier when you have the data you need. Stay in compliance with COGZ Reports.

Why is Preventive Maintenance Software Critical?

Preventive Maintenance Software is important because it schedules and tracks your preventive maintenance tasks. Organizing and prioritizing your tasks will make sure that you complete tasks on time and never forget one. Timely preventive maintenance stops breakdowns before they happen. Breakdowns cannot be eliminated, but decreasing the number of breakdowns substantially reduces maintenance costs and increases profitability.

CMMS Software also tracks spare parts inventory for your equipment. Tracking and organizing your inventory allows you to keep the parts that you need on hand when you need them. Having parts in stock reduces equipment downtime allowing for additional cost savings. A preventive maintenance system will also track labor and materials costs for your equipment. Having all of your maintenance information at your fingertips allows you to make the right decisions. Proper maintenance planning and maintenance management with complete data will help you to take your maintenance department to the next level.

Challenges of Preventive Maintenance

Preventive Maintenance when performed properly comes with a plethora of benefits including cost savings, extended equipment lifespans and improved production levels. It is important to understand that there are several challenges associated with implementing a preventive maintenance program. All of these challenges may be overcome with proper organization, prioritization and powerful CMMS Software. Challenges may include:

- Allocating technician time

- Upfront costs

- Mindset shift

- Scheduling Downtime

- Risk of Over Maintenance

- Resource Allocation

Preventive Maintenance Software Reporting and Compliance

Documenting Preventive Maintenance is a critical step toward meeting compliance and audit expectations. Preventive Maintenance Software provides various reports which will allow you to perform real time data analysis. Easily get the data you need to make data driven management decisions. Have the confidence to justify increased staffing requirements or tighten up maintenance schedules.

- Work Order History

- Preventive Maintenance Percent Completion

- Inventory Activity History

- Preventive Maintenance Forecasting

- Scheduling Downtime

- Equipment Cost History

Never Forget Preventive Maintenance Again

Preventive Maintenance Software ensures that your critical PMs will never slip through the cracks. Automatically schedule PMs and utilize reminder tools and reports to keep work on track.

COGZ Reviews

Customer Testimonials – Customer Success Stories.

Trusted Preventive Maintenance Software

COGZ is a proven CMMS Solution that has been driving bottom lines results for over twenty-five years. Powerful software with comprehensive features will help you take a proactive approach to maintenance. Our user friendly preventive maintenance software manage your work orders, decreases downtime and improves production and profitability. See for yourself how COGZ can help you save time and money today with our Free Trial.

Preventive Maintenance Success

At COGZ, we understand that the heart of any successful operation lies in the efficiency of its maintenance practices. Our Preventive Maintenance Software not only simplifies your maintenance tasks but also empowers your team to focus on what truly matters—maximizing productivity and minimizing downtime. With real-time data at your fingertips, you can make informed decisions that drive your business forward. Imagine a world where your equipment runs flawlessly, your maintenance team feels supported, and your operational costs are kept in check. That’s the COGZ promise. Join the ranks of satisfied customers who have transformed their maintenance strategies and experience the difference that proactive management can make.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.